Momentive RTV 106

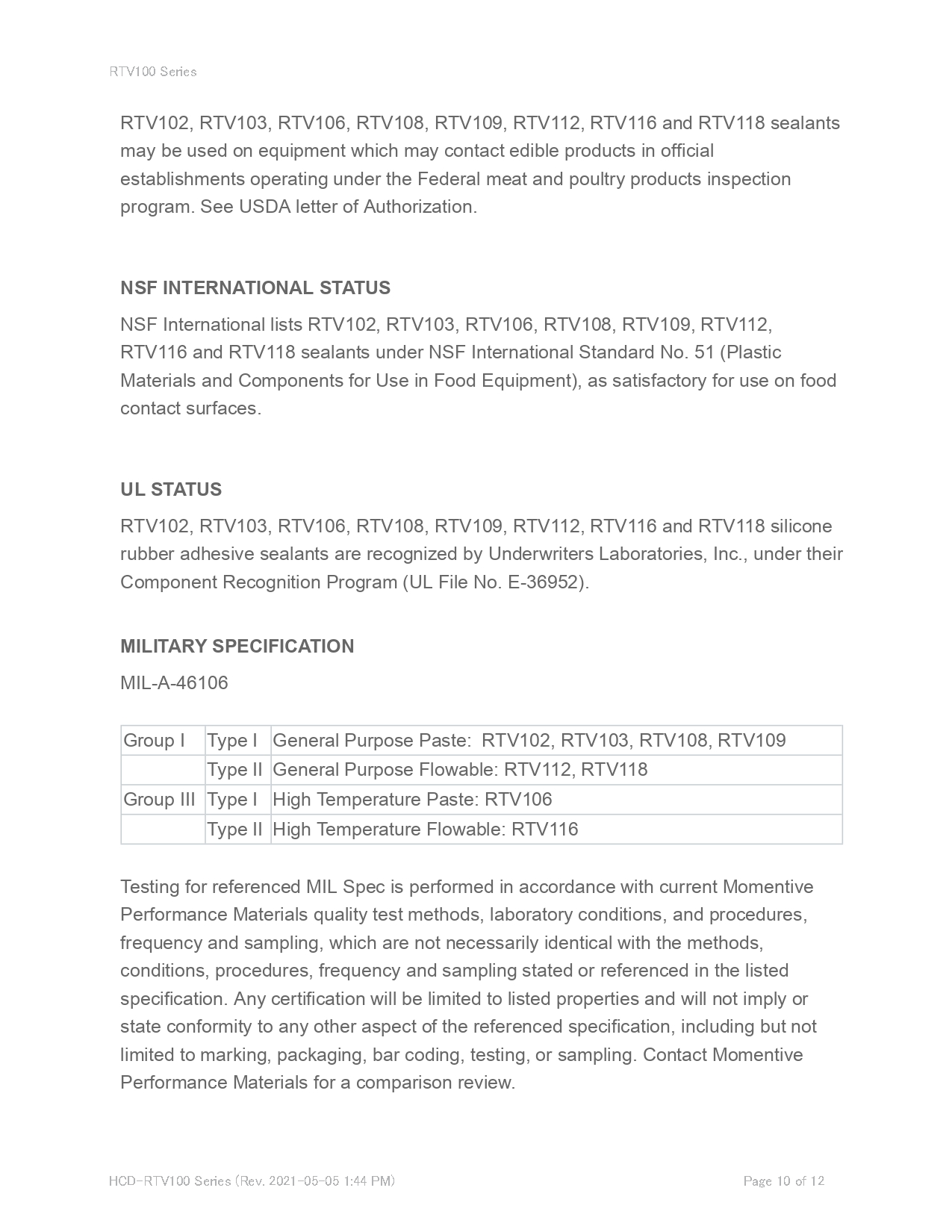

Momentive RTV 106 (also sold under brands like “SnapSil RTV106”) is a high-performance, one-component, moisture-curing silicone sealant specifically engineered for demanding, high-temperature applications. It cures into a durable, resilient silicone rubber and meets stringent certifications, including MIL-A-46106B, FDA, USDA, NSF 51, and UL recognition.

Key Features

High-temperature resistance: Handles up to 260 °C continuously, with short-term exposure tolerating up to 315 °C.

One-part, easy-to-use paste: Applies like a caulk—suitable for vertical and overhead surfaces—curing at room temperature with moisture.

Versatile surface compatibility: Adheres without primer to metals, glass, ceramics, silicone rubber, and some rigid plastics.

Broad regulatory approvals: Certified for food-contact applications—FDA 21 CFR 177.2600, USDA, NSF 51—and recognized by UL.

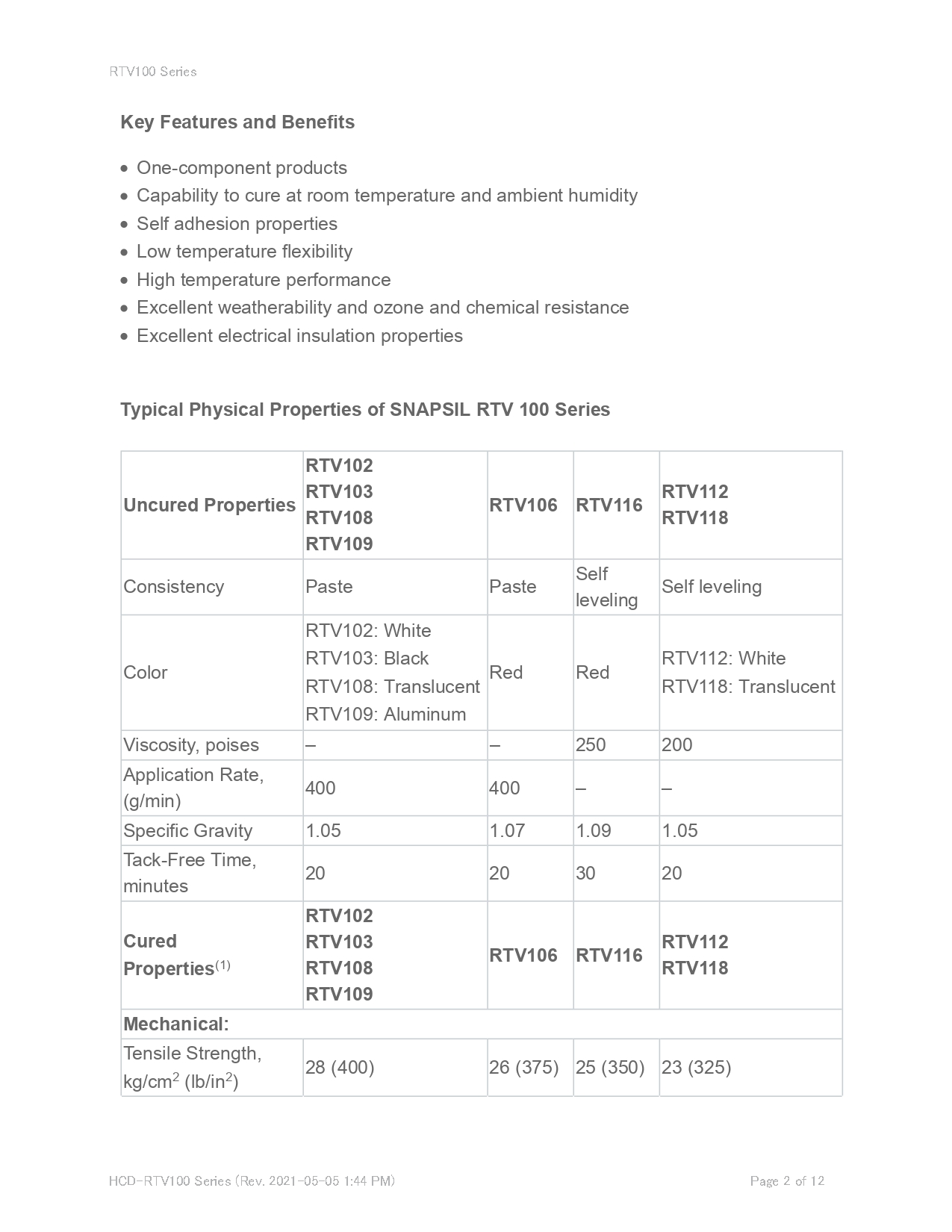

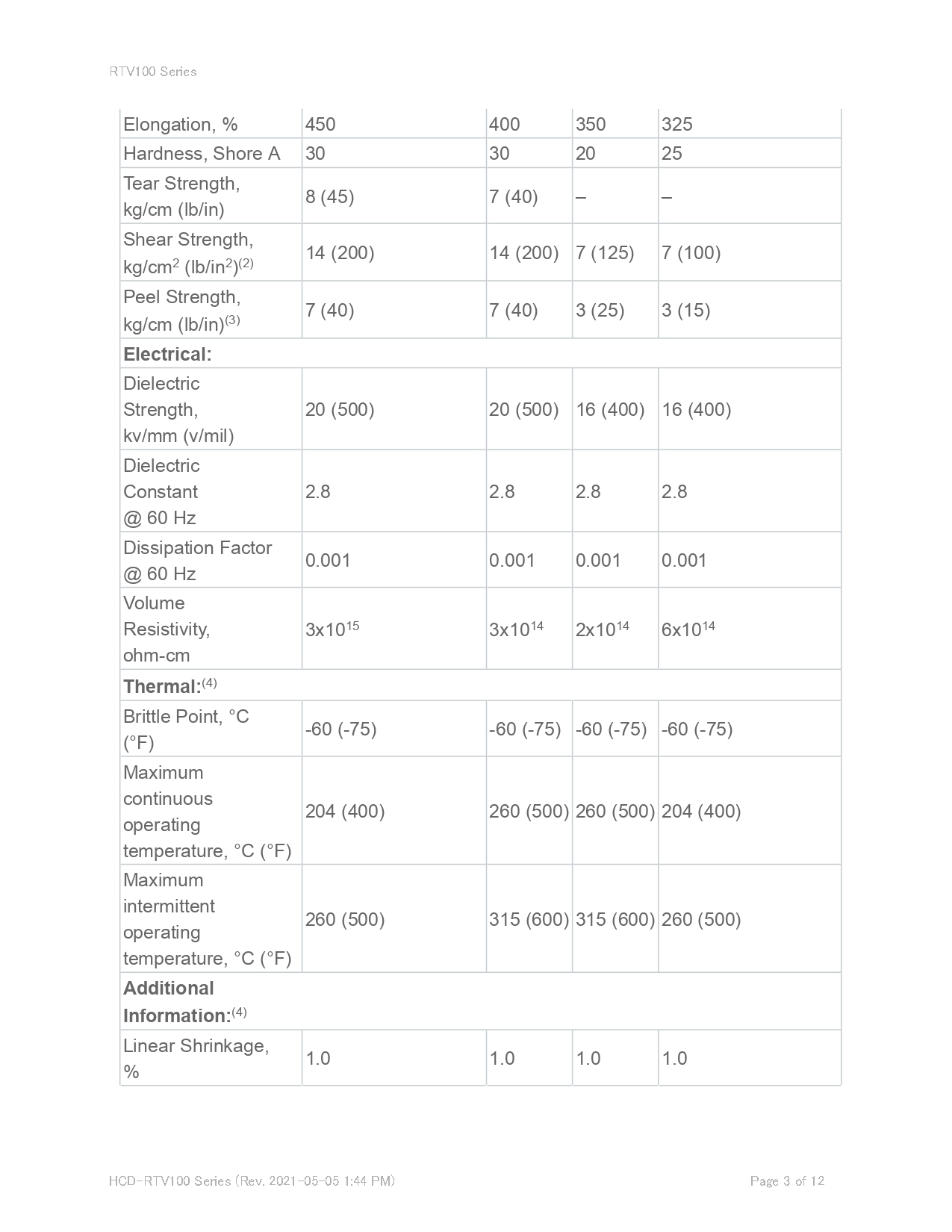

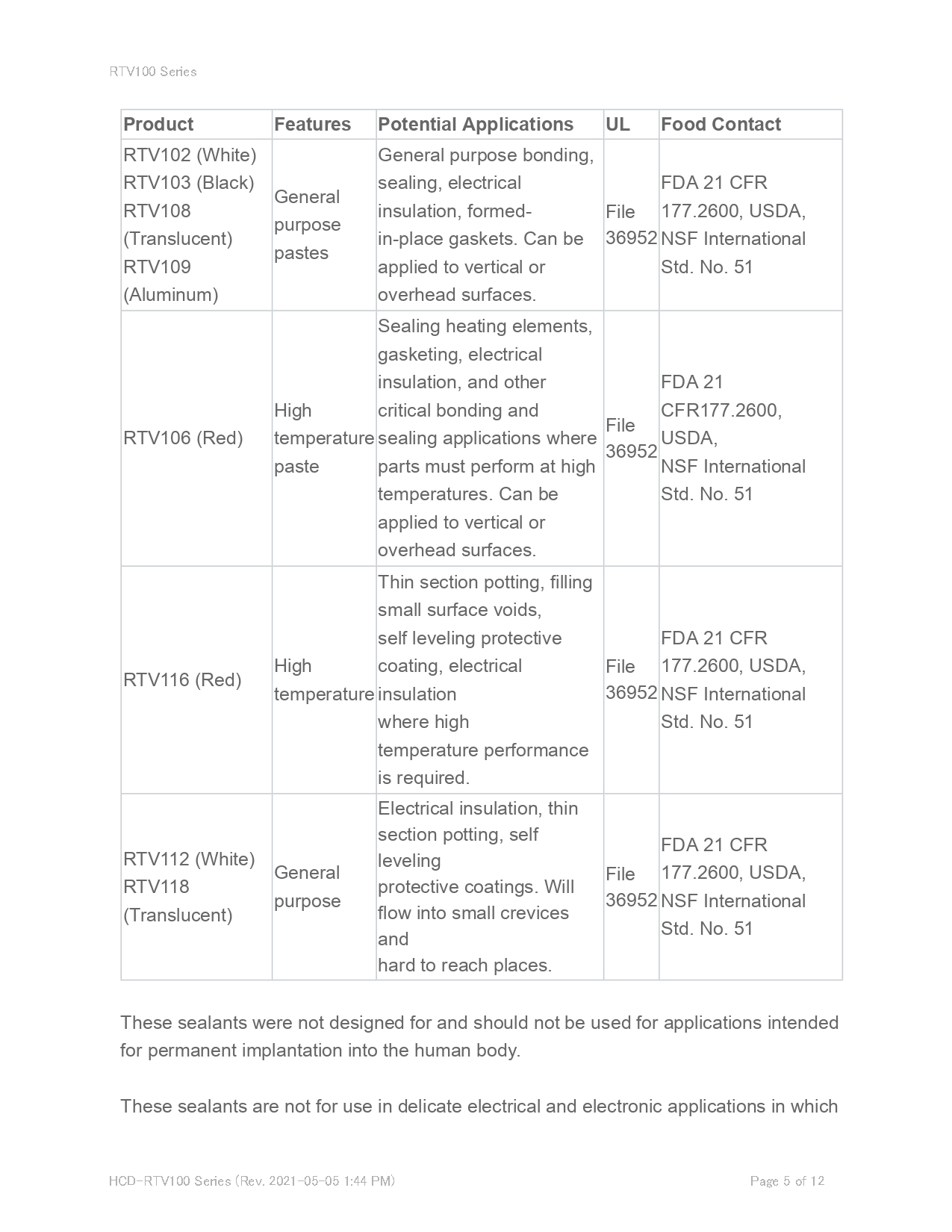

Technical Specifications | |

| Property | Specification |

| Consistency | Paste |

| Color | Red |

| Specific Gravity | ~1.07 g/cm³ |

| Tack-Free Time | ~20 minutes at 25 °C / 50% RH |

| Tensile Strength | ~26 kg/cm² (≈ 375 psi) |

| Elongation at Break | ~400% |

| Shore A Hardness | ~30 |

| Tear Strength | ~7 kg/cm |

| Shear Strength | ~14 kg/cm² |

| Peel Strength | ~7 kg/cm |

| Dielectric Strength | ~20 kV/mm |

| Volume Resistivity | ~3×10¹⁴ Ωcm |

| Maximum Continuous Temp | 260 °C |

| Maximum Short-Term Temp | 315 °C |

| Brittle Point | –60 °C |

| Linear Shrinkage | ~1% |

| Thermal Conductivity | ~0.0005 cal/sec/cm²°C |

| Application Thickness Limit | ≤ 6 mm (1/4 in) — thicker layers can impede curing. |

Applications

RTV 106 excels in scenarios demanding both temperature and regulatory performance:

Sealing heating elements in appliances or industrial equipment

Creating high-temperature gaskets (e.g., ovens, engines)

Electrical insulation where high heat or food contact may be involved

Sealing components in cooking/catering equipment, ventilation systems, pumps, or automotive assemblies.

Safety & Handling

Curing release: Emits acetic acid vapor (characteristic vinegar odor); ensure proper ventilation.

Thin application preferred: Keep bead thickness under 6 mm to ensure full cure.

Surface prep: Clean, dry surfaces free from dirt, oil, or rust; no primer required for most surfaces, but use recommended primers for challenging substrates.

Handling and storage: Use in well-ventilated areas; wear gloves and eye protection. Store sealed in cool, dry locations.